Tecnopiu Product Catalogues

Tecnopiu Products for Marine

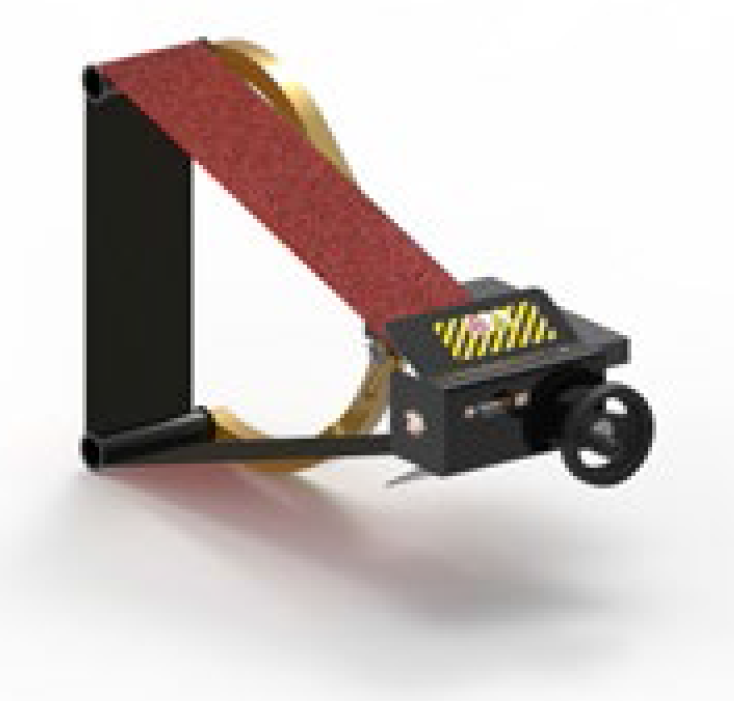

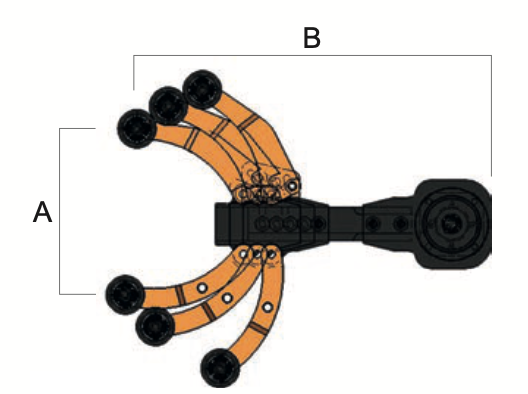

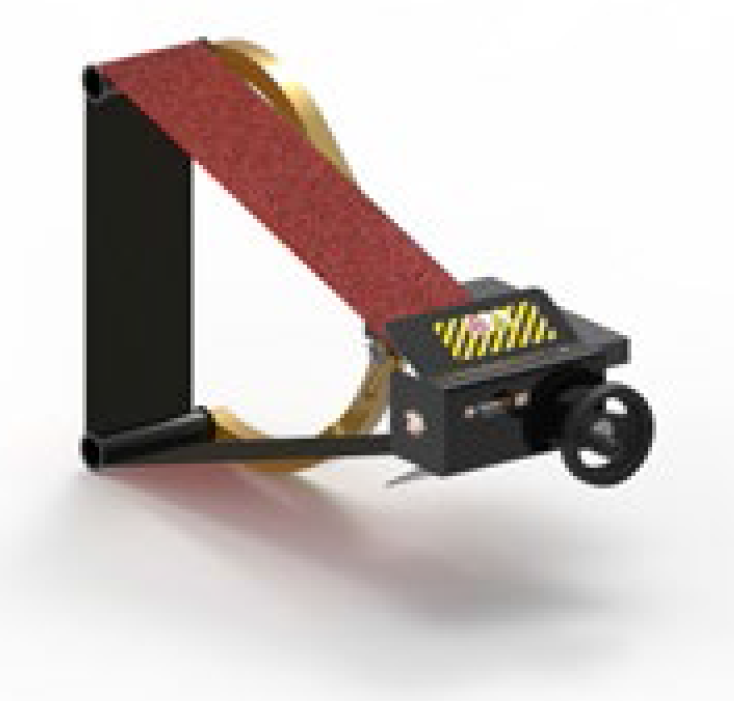

A tool for sanding and refining bars for conventional lathes, designed in accordance with ISO 23125 standards 6.2.1 (prohibition to use hands for work executions) which replaces with maximum safety, the same dangerous operation usally performed by hands.

The device is fixed to the existing toolcase turret of lathe.

The particular shape of the device and the tension springs allow to sand bars of different diameters. In order to keep always efficient the abrasive side, the belt can be rotated by means of the specific crank.

The following device is available in three different sizes with spare abrasive belts of different grit.

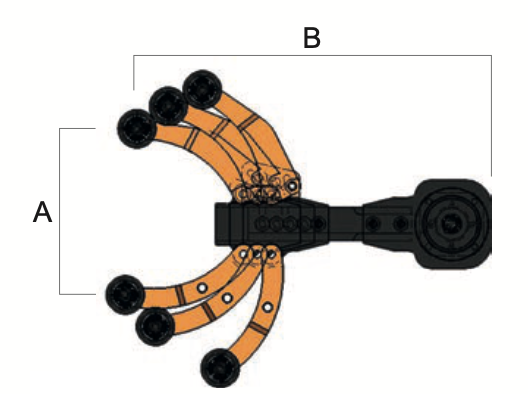

A tool for sanding and refining bars for conventional lathes, designed in accordance with ISO 23125 standards 6.2.1 (prohibition to use hands for work executions) which replaces with maximum safety, the same dangerous operation usally performed by hands.

The device is fixed to the existing toolcase turret of lathe.

The particular shape of the device and the tension springs allow to sand bars of different diameters. In order to keep always efficient the abrasive side, the belt can be rotated by means of the specific crank.

The following device is available in three different sizes with spare abrasive belts of different grit.

A tool for sanding and refining bars for conventional lathes, designed in accordance with ISO 23125 standards 6.2.1 (prohibition to use hands for work executions) which replaces with maximum safety, the same dangerous operation usally performed by hands.

The device is fixed to the existing toolcase turret of lathe.

The particular shape of the device and the tension springs allow to sand bars of different diameters. In order to keep always efficient the abrasive side, the belt can be rotated by means of the specific crank.

The following device is available in three different sizes with spare abrasive belts of different grit.

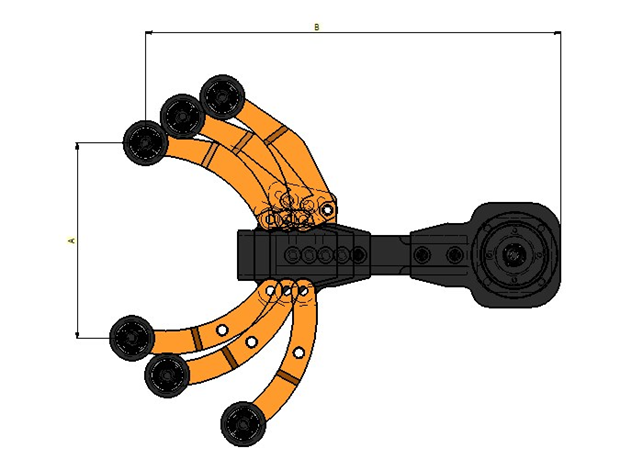

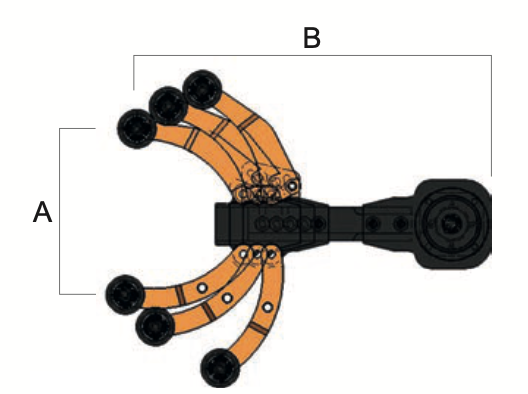

A new tool for sanding and refining bars for conventional lathes, with automatic movement of the abrasive belt, designed in accordance with ISO 23125 6.2.1. p (prohibition to use hands for work execution), which replaces, with maximum safety, the same dangerous operation usually performed by hands.

The device is fixed to the existing toolcase turret of lathe and, it’s particular shape, with three different opening position of the anterior arms of support, allows to sand bars of different diameters.

Thanks to the tension springs the belt always adheres in the best way.

The perfect efficiency of the abrasive part of the sanding belt is guaranteed by an automatic sliding system (Patented) which exploits the rotating movement of the piece worked.

The device is available in three sizes of 25, 50 and 100 mm with different grit.

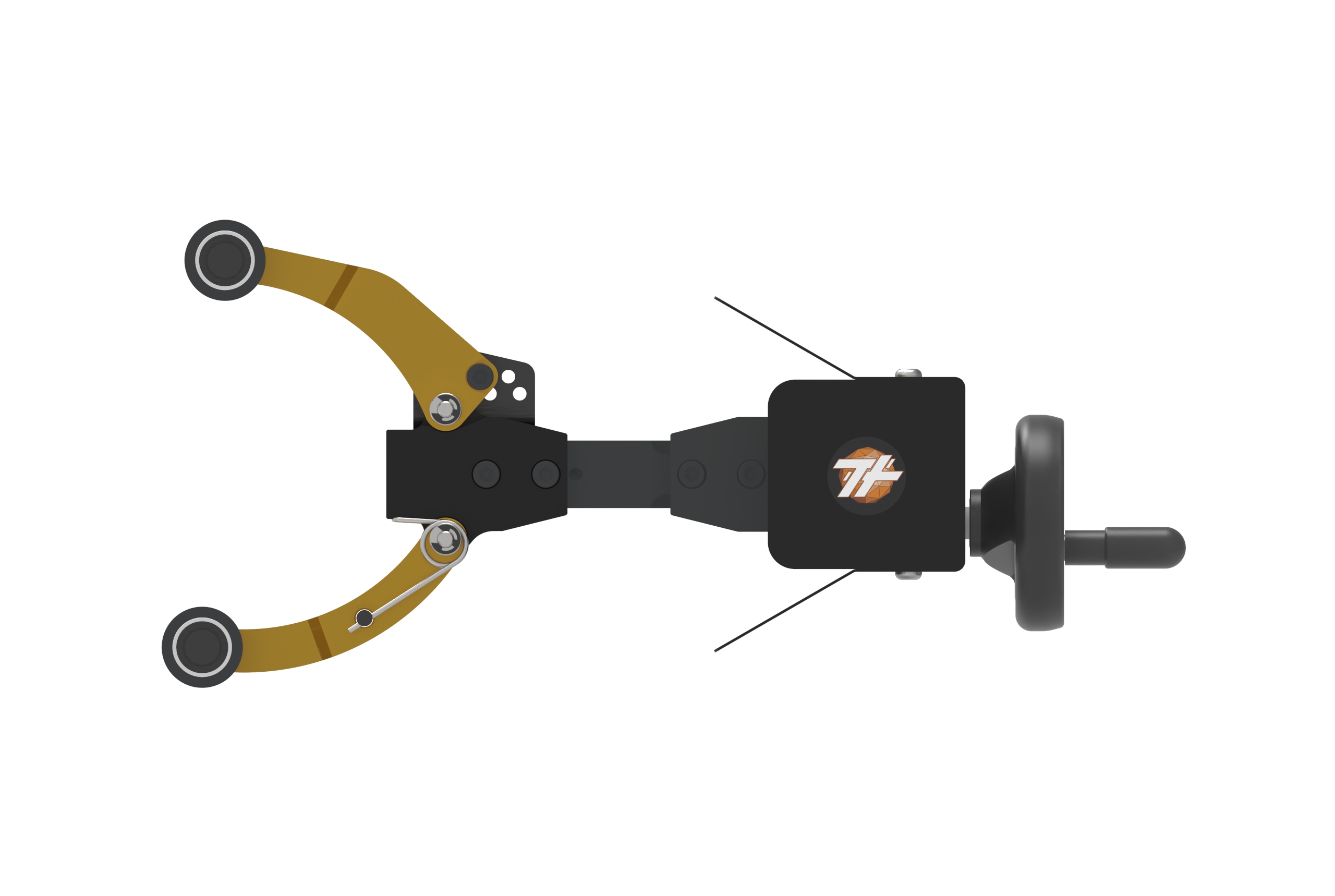

A new tool for sanding and refining bars for conventional lathes, with automatic movement of the abrasive belt, designed in accordance with ISO 23125 6.2.1. p (prohibition to use hands for work execution), which replaces, with maximum safety, the same dangerous operation usually performed by hands.

The device is fixed to the existing toolcase turret of lathe and, it’s particular shape, with three different opening position of the anterior arms of support, allows to sand bars of different diameters.

Thanks to the tension springs the belt always adheres in the best way.

The perfect efficiency of the abrasive part of the sanding belt is guaranteed by an automatic sliding system (Patented) which exploits the rotating movement of the piece worked.

The device is available in three sizes of 25, 50 and 100 mm with different grit.

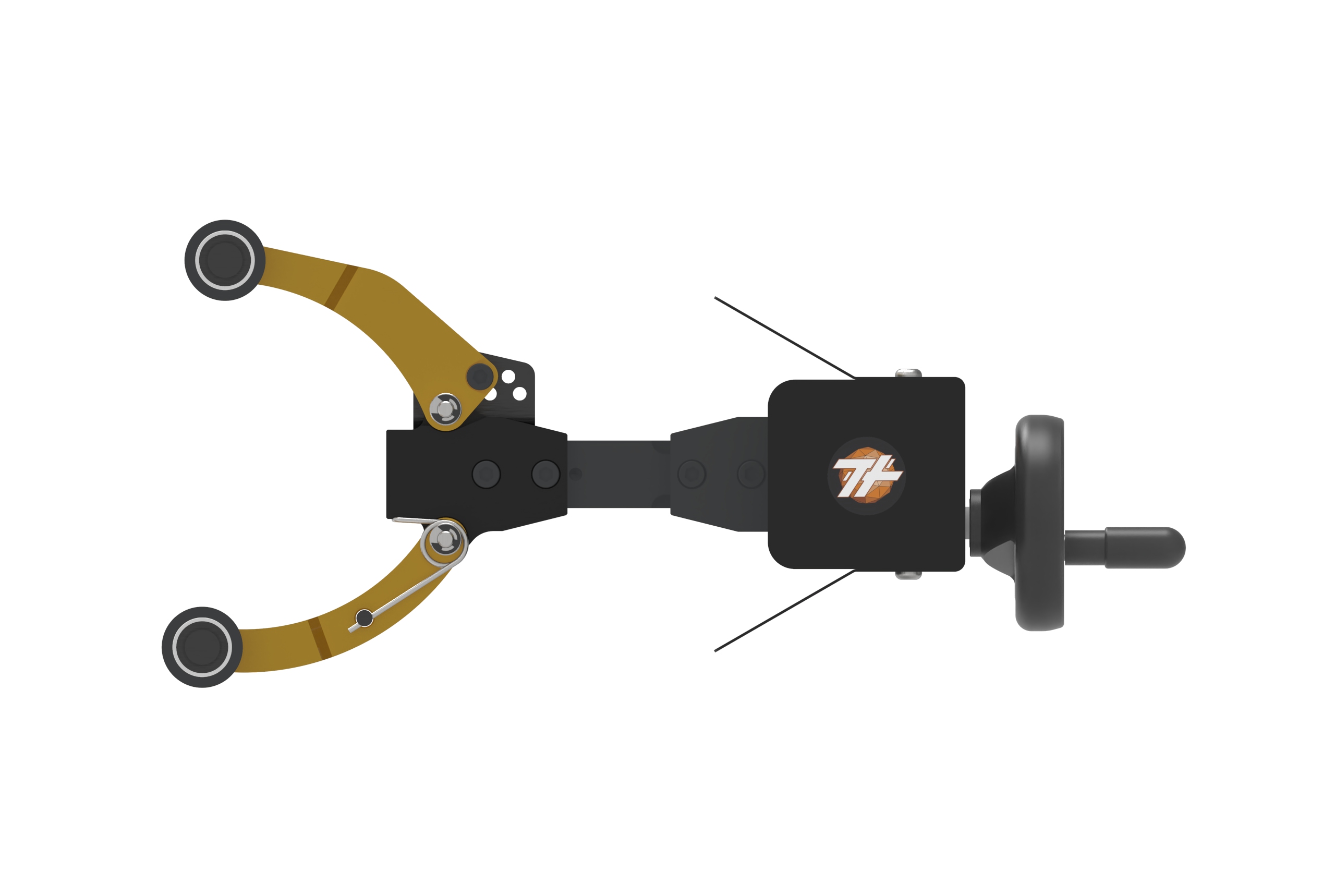

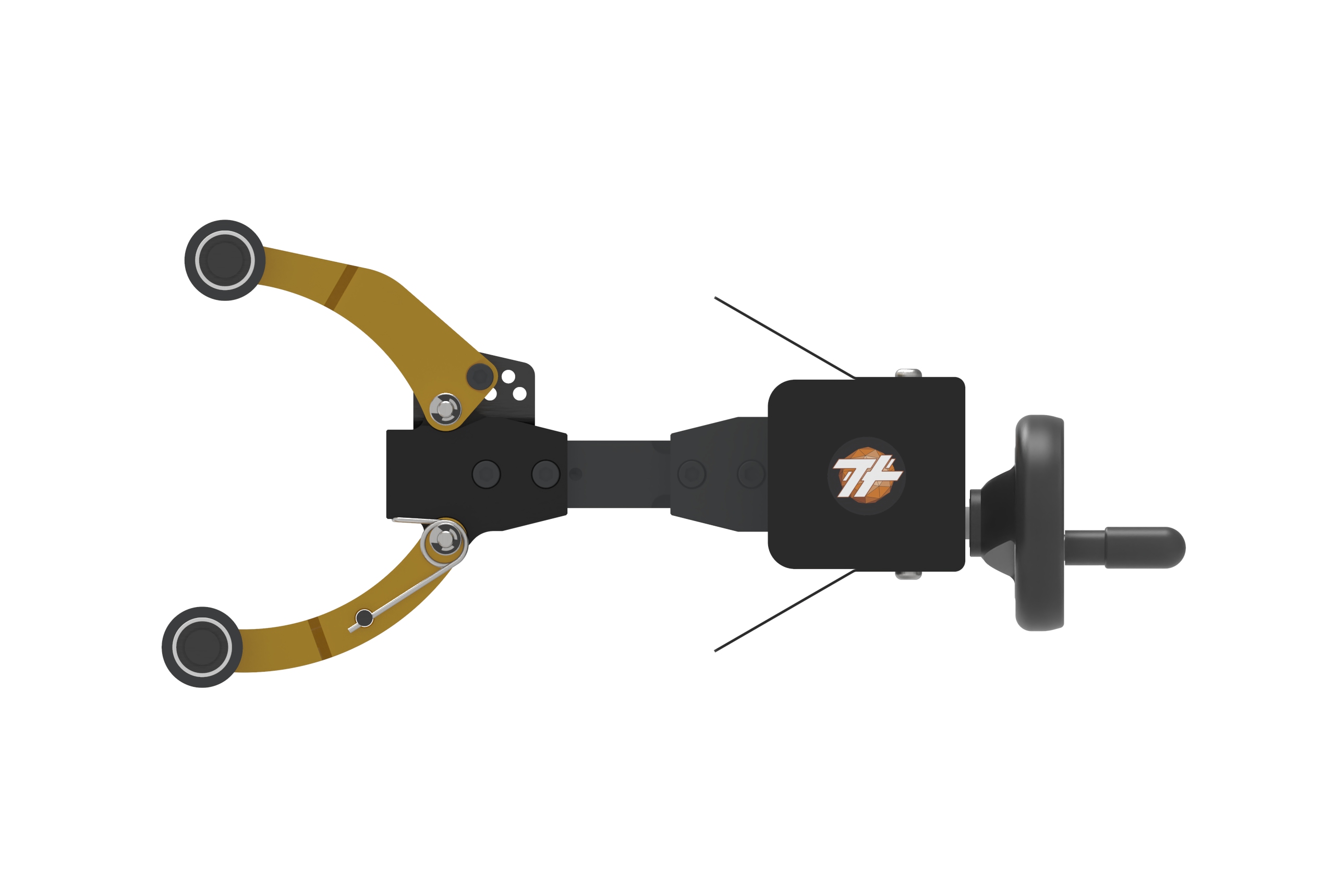

A new tool for sanding and refining bars for conventional lathes, with automatic movement of the abrasive belt, designed in accordance with ISO 23125 6.2.1. p (prohibition to use hands for work execution), which replaces, with maximum safety, the same dangerous operation usually performed by hands.

The device is fixed to the existing toolcase turret of lathe and, it’s particular shape, with three different opening position of the anterior arms of support, allows to sand bars of different diameters.

Thanks to the tension springs the belt always adheres in the best way.

The perfect efficiency of the abrasive part of the sanding belt is guaranteed by an automatic sliding system (Patented) which exploits the rotating movement of the piece worked.

The device is available in three sizes of 25, 50 and 100 mm with different grit.

Abrasive Belts for Manual and Automatic Belt Holders.

Available in grit: 80, 100, 120, 150, 180, 220, 240 & 320

| M10 & A10 25 x 762 MM | M20 & A20 50 x 915 MM | M40 & A40 100 x 1372 MM | |

|---|---|---|---|

| GRIT 80 | AB080-S1 | AB080-S2 | AB080-S4 |

| GRIT 100 | AB100-S1 | AB100-S2 | AB100-S4 |

| GRIT 120 | AB120-S1 | AB120-S2 | AB120-S4 |

| GRIT 150 | AB150-S1 | AB150-S2 | AB150-S4 |

| GRIT 180 | AB180-S1 | AB180-S2 | AB180-S4 |

| GRIT 220 | AB220-S1 | AB220-S2 | AB220-S4 |

| GRIT 240 | AB240-S1 | AB240-S2 | AB240-S4 |

| GRIT 320 | AB320-S1 | AB320-S2 | AB320-S4 |

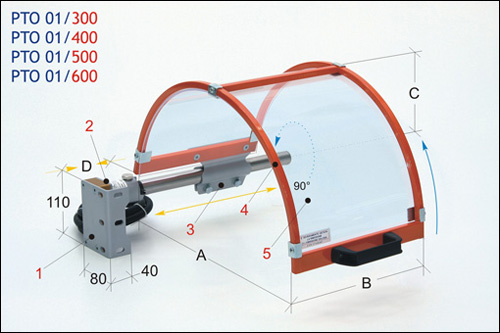

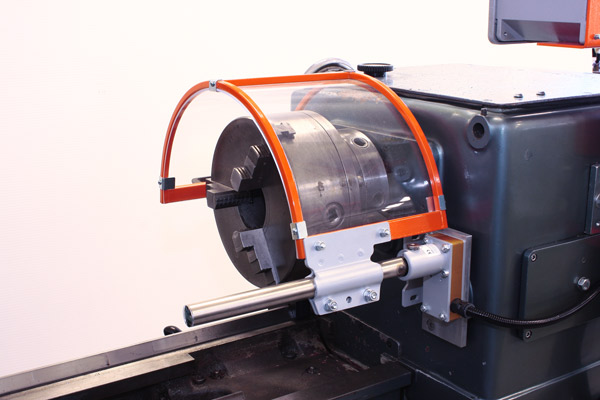

Classic safety guard equipped with steel-framed shield.

Protects the operator from direct contact with the upper part of the chuck lathe and from lubricant-coolant projection.

Frontally and laterally attachable to the lathe base.

Equipped with semicircular shield.

Uniquely positionable right near the machine head.

Comes with safety micro-switch for auto-off functionality.

Available in various dimensions.

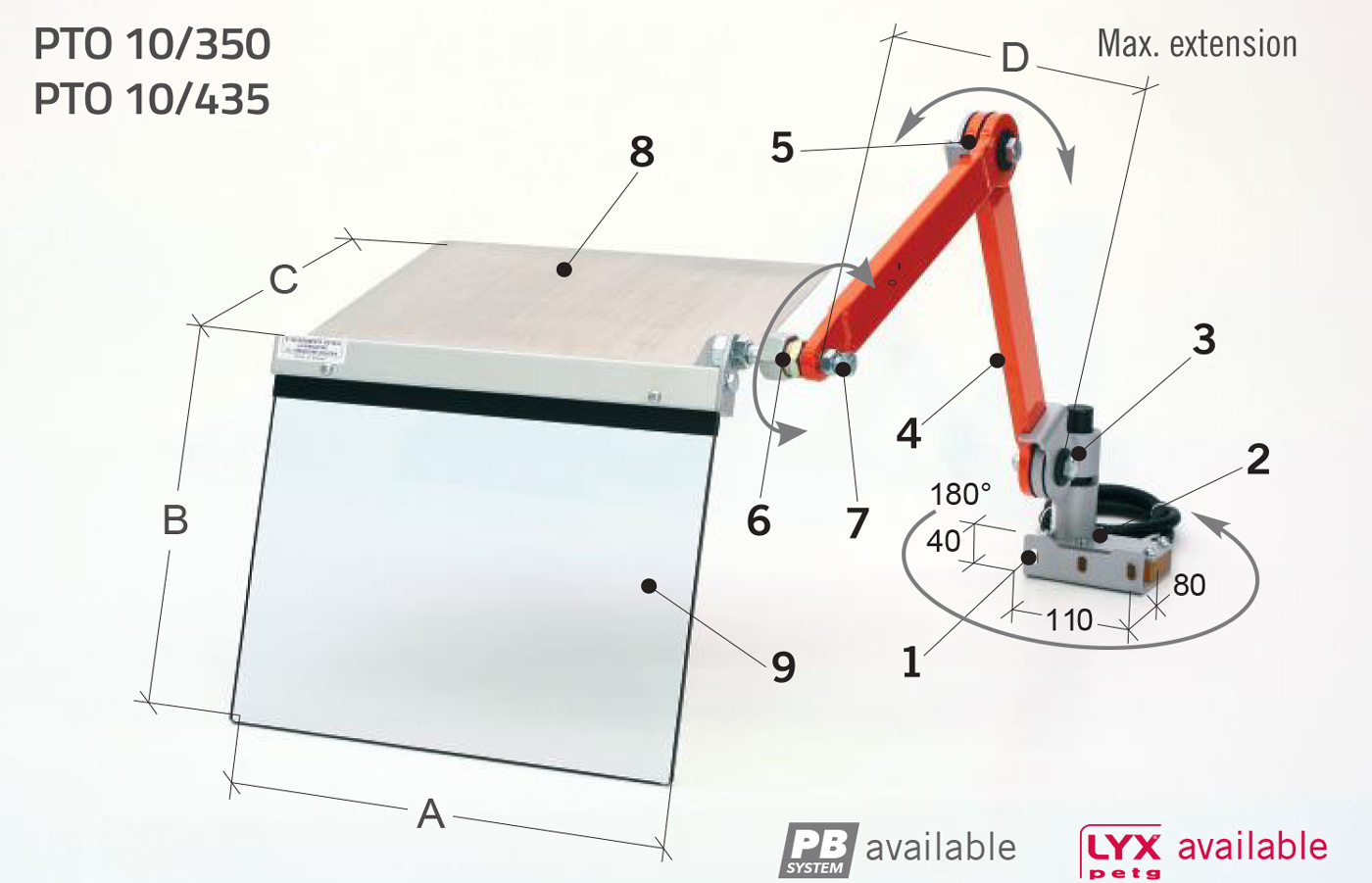

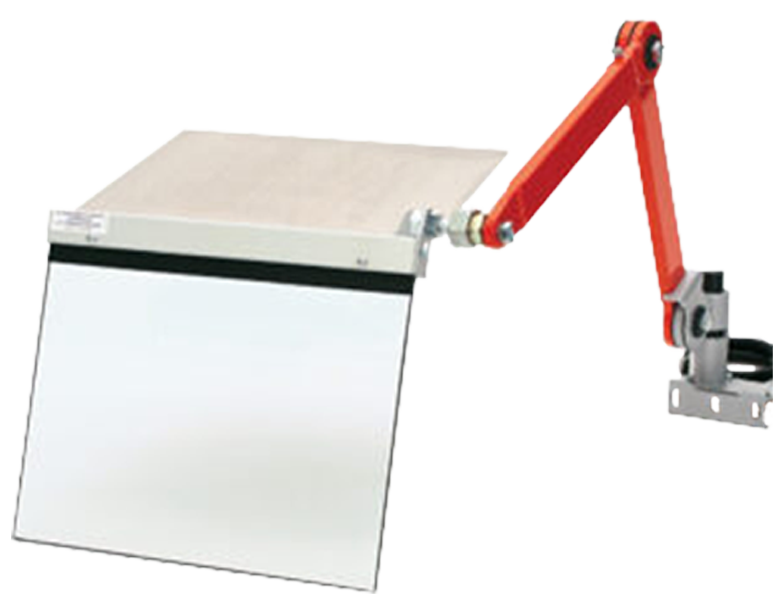

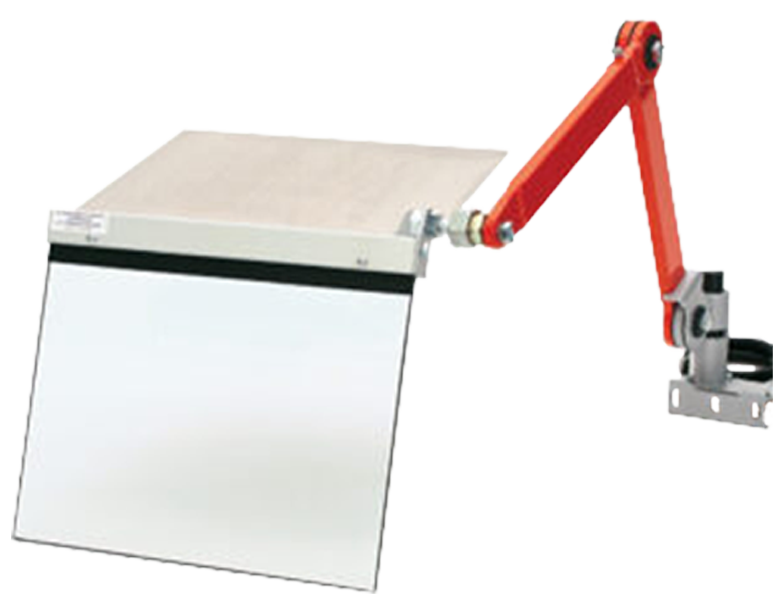

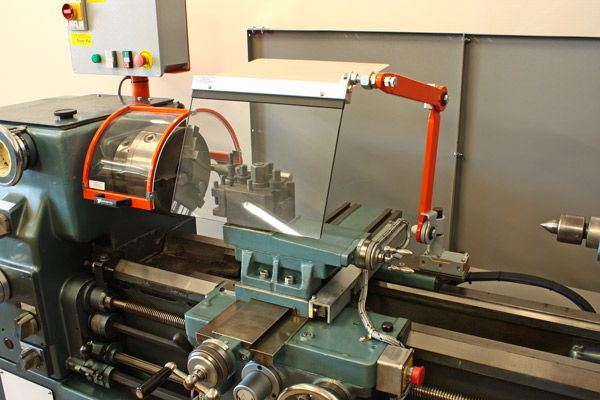

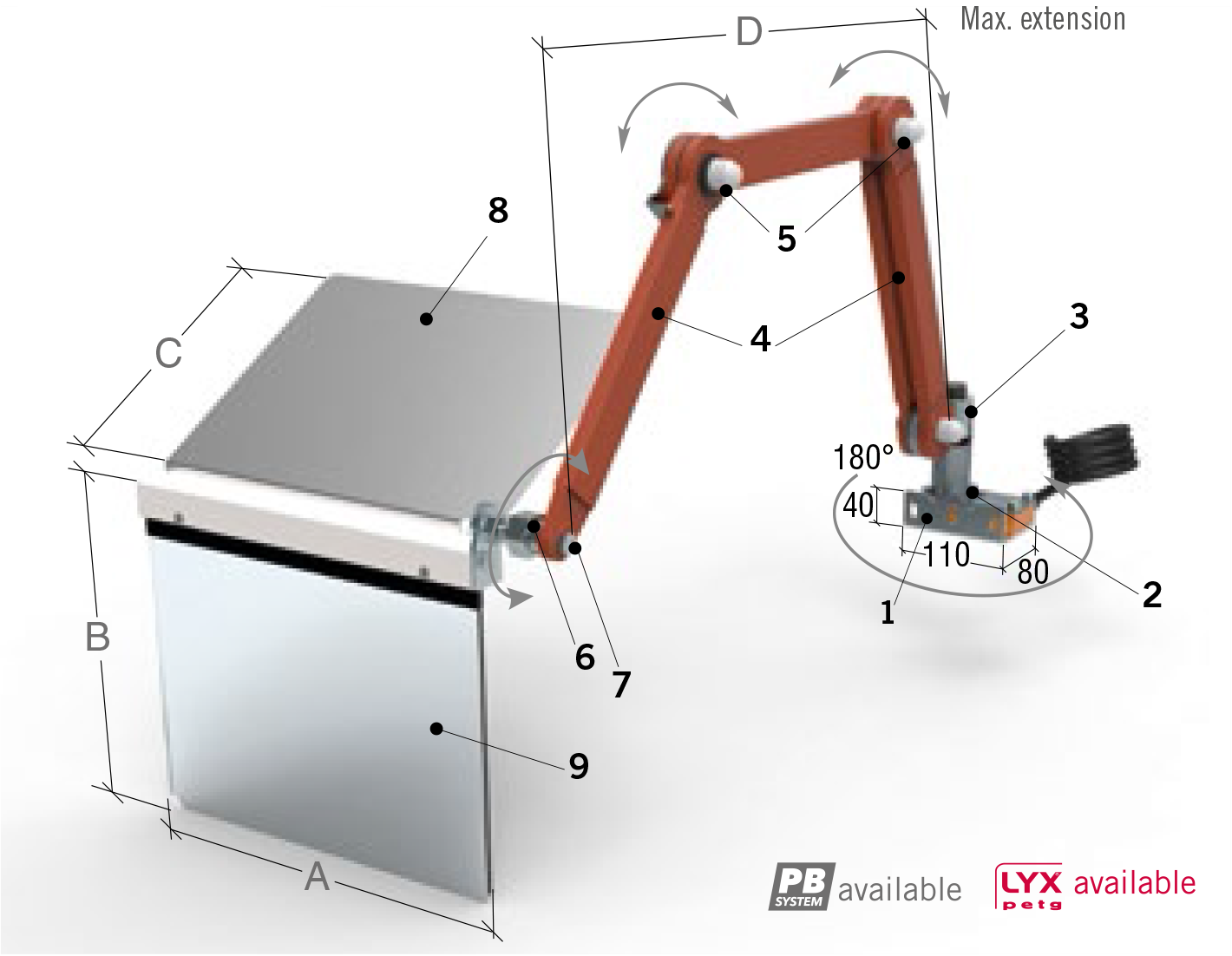

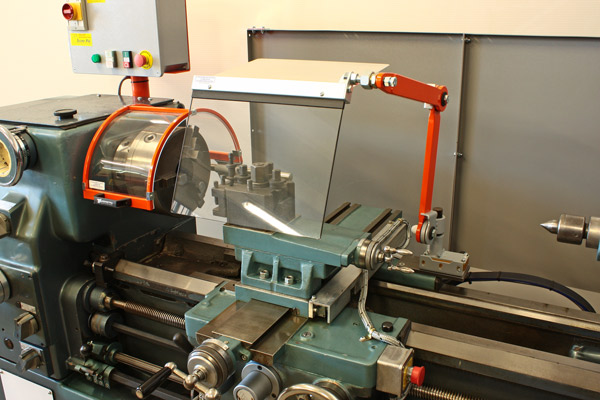

PTO 10 is a multi-adjustable safety guard, designed to be installed on the longitudinal lathe carriage.

Combined with the chuck safety guard (PTO 01), provides an excellent protection of the operator.

Protects the operator from direct contact with rotating components of the chuck and from the projection of shavings and lubricant-coolant.

Attachable behind the longitudinal carriage.

The shield, supported by an articulated arm of 2 x 235 mm jointed segments, is completely adjustable and has an anti-shavings partition.

Ball socket joint provides 3D positioning.

Comes with safety micro-switch for auto-off functionality.

Available in various dimensions.

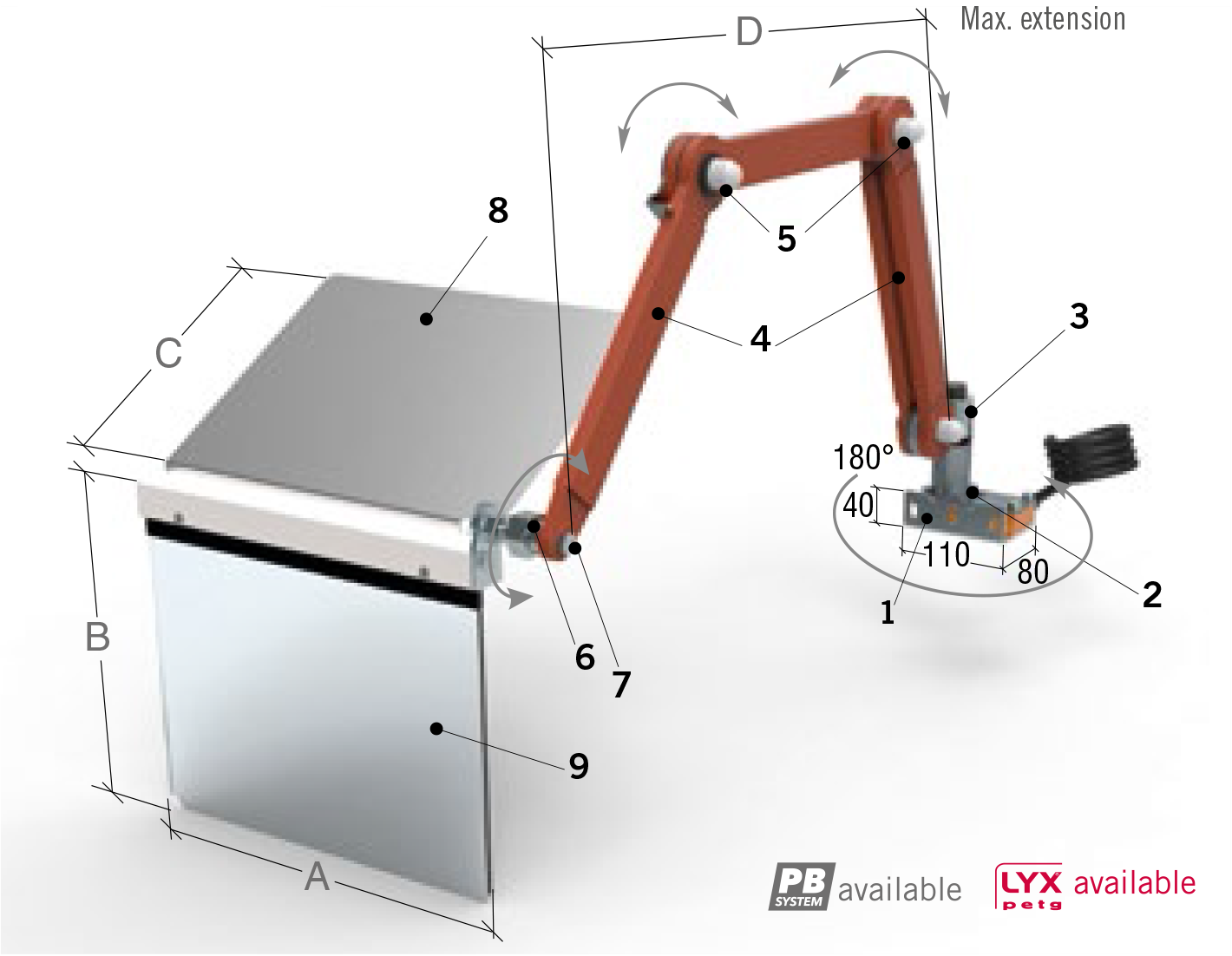

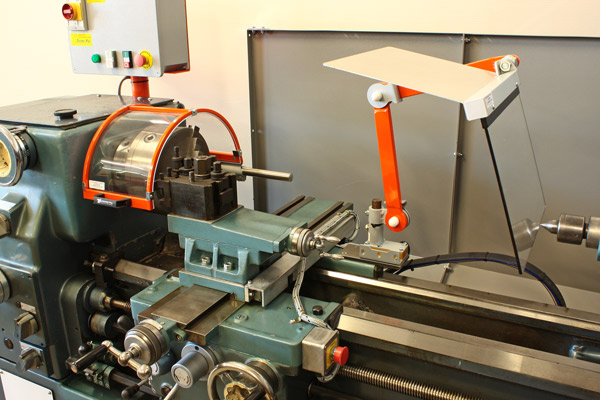

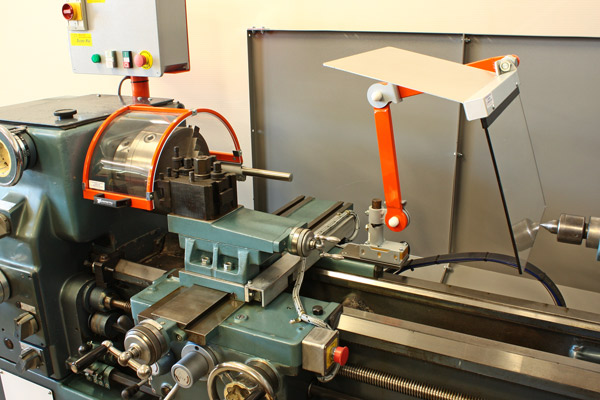

PTO 10 is a multi-adjustable safety guard, designed to be installed on the longitudinal lathe carriage.

Combined with the chuck safety guard (PTO 01), provides an excellent protection of the operator.

Protects the operator from direct contact with rotating components of the chuck and from the projection of shavings and lubricant-coolant.

Attachable behind the longitudinal carriage.

The shield, supported by an articulated arm of 3 x 235 mm jointed segments, is completely adjustable and has an anti-shavings partition.

Ball socket joint provides 3D positioning.

Comes with safety micro-switch for auto-off functionality.

Available in one size only.